Description

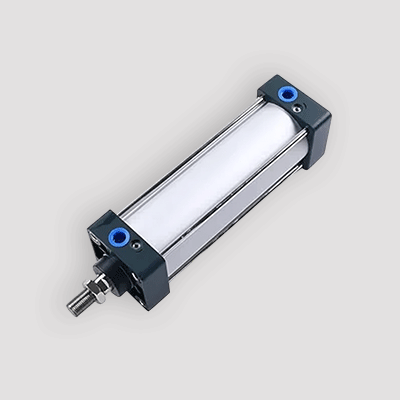

Pneumatic Cylinders are mechanical devices used to convert compressed air into linear motion for various industrial automation and material handling applications. They are widely used in manufacturing plants, packaging machines, conveyor systems, assembly lines, automotive industries and process automation systems. At Pandge, we offer all types of Pneumatic Cylinder models including single-acting, double-acting, compact, guided and heavy-duty cylinders to suit diverse industrial requirements.

Our Pneumatic Cylinders are manufactured using high-quality materials to ensure smooth operation, long service life and reliable performance even in demanding industrial environments. Designed for accuracy and consistent force output, Pandge Pneumatic Cylinders provide stable motion control with minimal maintenance. Their precision-engineered components ensure excellent sealing, low air leakage and efficient energy usage.

These cylinders are available in multiple bore sizes, stroke lengths and mounting options for easy integration with different automation systems. With robust construction, corrosion-resistant finishes and dependable performance, Pandge Pneumatic Cylinders help improve machine efficiency, reduce downtime and enhance overall productivity in industrial applications.

Key Features of Pneumatic Cylinder

- Smooth and precise linear motion control

- Single-acting and double-acting models available

- Wide range of bore sizes and stroke lengths

- High-quality seals for low air leakage

- Durable and corrosion-resistant construction

- Easy mounting and system integration

- Low maintenance and long service life

- Suitable for light and heavy-duty applications